Surface Modification of Wood Polymer Composites

Who’s Involved?

- Douglas Gardner (Faculty)

- Gloria Oporto (Grad. Student)

- Ryan Mills (Grad. Student)

Research Introduction

This project is involved with understanding the surface and adhesive bonding (gluing) characteristics of wood strands, fibers, particles, and other solid residues being generated from the forest bio-refinery processes. An improved understanding of surfaces will enable us to create composite materials that are as strong or stronger than glass oil-based polymers. Products from sheet molding to common plastic containers used by businesses and consumers might be wood based rather than petroleum based.

This project is involved with understanding the surface and adhesive bonding (gluing) characteristics of wood strands, fibers, particles, and other solid residues being generated from the forest bio-refinery processes. An improved understanding of surfaces will enable us to create composite materials that are as strong or stronger than glass oil-based polymers. Products from sheet molding to common plastic containers used by businesses and consumers might be wood based rather than petroleum based.

Research Details

My work on the project is involved with understanding the surface and adhesive bonding (gluing) characteristics of wood strands, fibers, particles, and other solid residues being generated from the forest biorefinery processes.

Many of the solid residues being produced in the forest biorefinery will be used for composite material manufacturing, so we need to develop and understanding of surface properties at the millimeter length scale down to the nano or molecular length scale. This improved understanding of surfaces will enable us to better engineer composite materials from the forest biorefinery processed.

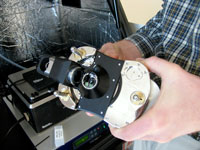

We have been characterizing the adhesive bonding properties of modified wood plastic composite surfaces that have been modified by physical (water and heat treatment), energetic (flame treatment), chemical (chromic acid) and mechanical (sanding) means.

Techniques used to characterize the surfaces of WPCs include: contact angle analysis (surface energy), X-ray photoelectron spectroscopy (XPS), infrared spectroscopy, scanning electron microscopy, and profilometry. Results indicate that a combination of flame and water treatment provides and WPC surface that can successfully form structural adhesive bonds with epoxy resin. This work is being done by Gloria Oporto, Ph.D student, Forest Resources. Additional work is applying the technique of inverse gas chromatography on characterizing the surface characteristics (functional groups and surface energy) of biobased fibers (Kenaf and wood) that are being used as potential replacements in sheet molding compound (SMC) composites.

This work is being done by Ryan Mills, Ph. D. student, Forest Resources. The research being performed on the surface characterization of wood and lignocellulosic materials by a variety of surface analysis techniques is providing a framework and evaluation protocols for solid materials being produced in the forest biorefinery research project. These surface evaluation protocols will enable us to thoroughly examine the adhesion bonding potential of forest bioproduct solids in composite materials.

As we work towards understanding wood and lignocellulosic surface properties on length scales from macroscopic to nanoscale, we can provide a framework for evaluating similar material systems, and perhaps provide an understanding of composite material properties across multiple length scales. One goal of the research is to produce new forest based composite materials that can displace the dependence on oil-based polymers, and use biobased rather than glass fibers.

What’s New on this Project

Ryan Mills has successfully used wood fibers and polymers to fortify sheet molding panels making them even stronger and lighter than panels using oil based polymers. His research indicates however, that the hemicellulose fibers in the composite absorb water so he has begun experimenting with various composite combinations and coatings to prevent retention of moisture.